What is Drysnow? Fine dry ice blast cleaning

Drysnow is the cleaner that blasts the fine dry ice powder produced from a liquid CO2 cylinder. Drying and waste treatment is not necessary due to sublimation of the dry ice powder. Suitable for cleaning precision parts. It can also be installed into production line.

Characteristics

- Particulates, burrs and oil can be removed by blasting fine dry ice powder without damage.

- Water, organic solvent, drying process and waste treatment is not necessary

- CO2 is not hazardous material and thus the cleaning is environmental friendly process.

- Snow powder sublimes rapidly and does not cause a secondary dirt.

- Handy type and in-line type are available.

Benefits of Drysnow cleaning

Dry ice particles are supplied from CO₂ cylinder

- The temperature control of the carrier gas allows continuous operation without plugging of the snow particless.

- Flow rate can be controlled, enabling reduction of carbon dioxide gas consumption.

- ON/OFF switching is possible instantly.

*Since particles are generated by the gun near the jet outlet, the granulation phenomenon due to the capillary tube that is seen in general dry ice blasting does not occur.

Example videos (in Japanese)

- Work: Carbide parts

- Target for removal: Adhesive

- Work: Solar cell film

- Target for removal: Pattern residue

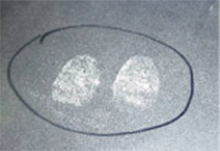

- Work: Glass plate

- Target for removal: Fingerprint

- Work: CMOS image sensor

- Target for removal: Dirt

- Work: Motor

- Target for removal: Oil and metal powder

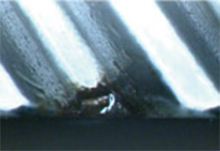

- Work: Auto parts

- Target for removal: Solder (<0.24mm)

- Work: OEL display device

- Target for removal: Glass particles

- Work: LCD terminal

- Target for removal: Dirt

- Work: Aluminum cylinder

- Target for removal: Oil

Since it cannot be confirmed visually, apply ink. If oil remains on the surface, it repels ink, and if it does not, it gets wet.

Overview

There are various methods of cleaning that are suitable for each subject.

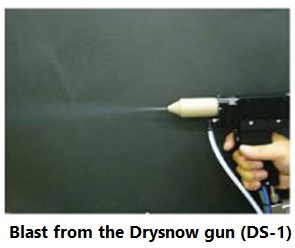

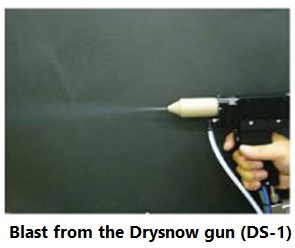

Our “Drysnow” is an effective cleaning system when water or organic solvents cannot be used and when the object must not be damaged. Drysnow sprays snow-like dry ice particles from a nozzle onto the object to be cleaned. As a result, dirt is removed and the sprayed dry ice sublimates completely, eliminating the need for a drying process. There are two types of Drysnow, a handy type (DS-1) and an in-line type (DS-2) to be introduced into production lines.

Things necessary

All you need is a CO2 cylinder, compressor air, and a power supply.

Mechanism

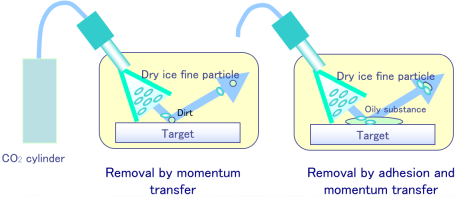

First, liquefied carbon dioxide is supplied from the cylinder. When this liquefied carbon dioxide gas is ejected into the atmosphere and depressurized, the temperature drops due to the Joule-Thomson effect. Then, dry ice, which is a solid, is generated from the liquid. This dry ice becomes snow-like fine particles. The dry ice jet, together with the heated compressor air stream, or carrier gas, is sprayed onto the object for cleaning.

Differences from standard dry ice blast cleaning

Standard dry ice blast cleaning equipment blows crushed dry ice in solid form. Therefore, the individual particles are large and hard. The cleaning power is strong, but because of the violent impact, there is a risk of damaging the object.

With our Drysnow, the dry ice particles are extremely small and soft like snow, making it possible to clean soft objects such as resins.

Functions of Drysnow

The dry snow gun can fine-tune the flow rate.

Therefore, it is possible to clean extremely delicate objects without damaging them.

In addition, since the ON / OFF response of the blasting is instantaneous, fine cleaning can be performed.

What kind of dirt is easy to remove?

Powder, dust, and other contaminants adhering to the surface can be easily cleaned. Drysnow can also be used to remove dirt particles that have penetrated deep into surface irregularities or are stuck and cannot be removed by air blow. Drysnow is also good at removing oil stains (e.g., fingerprints) that normally require liquid cleaning.

For more details, please refer to the cleaning example photos.

Types of Drysnow nozzles

Drysnow currently has three types of nozzles. As shown below, there are suitable cleaning objects for each.

- Mixed-flow type nozzle

This type of nozzle mixes a dry ice jet with a carry gas stream. This nozzle has the highest cleaning power due to the high momentum of the dry ice particles. Among the 3 types, the dry ice particles have the highest momentum, resulting in the highest cleaning performance. This is suitable for objects with small surface irregularities. - Center-flow type nozzle

This injection method has a narrow dry ice jet in the center and a carrier gas stream surrounding the outer sheath. It is suitable for cleaning the inside of a small diameter depression. This is because the narrow jet does not increase the pressure inside the depression, so the jet can reach the inside. - Round-flow type nozzle

This type has many jet outlets arranged in a circular pattern. Because the jet is split, only weakly adhering dirt is applied, but it is suitable for cleaning large flat surfaces.

Remarks

When dry ice particle collide to the cleaning object, static electricity is generated. Care should be taken when cleaning semiconductor circuits, etc. When using a commercially available static eliminator, a nozzle type (spot type) or other type of device that eliminates static with pinpoint accuracy is suitable. The static eliminating nozzle should be placed as close as possible to the colliding point between the jet and the object.

During cleaning, the surface of the object is cooled and condensation may occur. This condensation can cause watermarks. To prevent this, warmed carrier gas is used. To completely prevent condensation, dry air or dry nitrogen is used as the carrier gas, and the atmosphere is purged with these dry gases.