Supercritical CO₂ cleaning system No liquid waste. No drying process required.

Cleaning technology using the dissolving power of supercritical CO₂ is attracting attention in a wide range of fields as an environmentally friendly technology. Supercritical CO₂ has low surface tension, allowing it to penetrate into tight spaces and to clean semiconductor parts and precision components without destroying their microstructure.

Characteristics

- No drying process required

- Easy to recycle and reuse cleaning liquid

- No need to dispose of cleaning waste

Specifications

| Design pressure | 10MPa |

| Design temperature | 40℃ |

| Cleaning vessel volume | 12L |

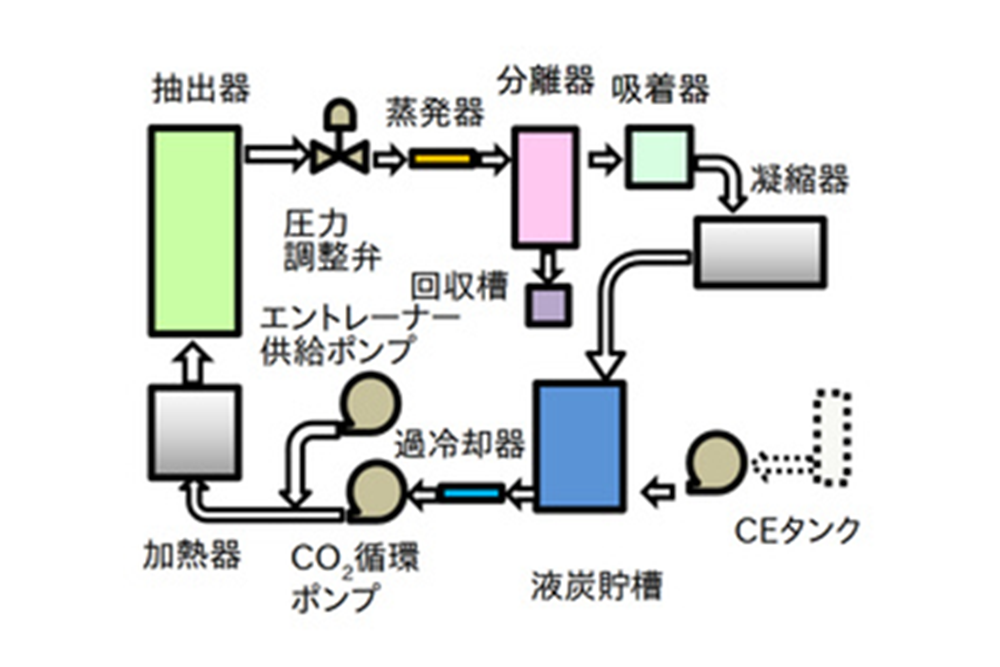

System configuration

- Cleaning vessel (with external heater and auto-open/close lid)

- Liquid CO₂ supply tank (with built-in condenser)

- Waste liquid recovery tank (with built-in heater)

- Chiller (5.5kw)

- Filter (switchable)

- Controller (touch panel)

Features

- Operating range is from subcritical to supercritical

- Separates carbon dioxide gas and residue contained in cleaning effluent

- Carbon dioxide gas is liquefied and reused

- Residue is highly concentrated because it does not contain washing solution

Object to be cleaned

- Textiles: Garment cleaning, removal of residual toxic substances

- Precision parts : Oil removal, solvent removal

- Semiconductor : Wafer, resist film removal, IT parts cleaning

Advantage

- Capable of cleaning water- and heat-sensitive parts

- No drying time required

- Composite assemblies can be cleaned

Options

- CO₂ recovery system

- Display monitor

*Various types of support are available upon consultation.